Smarter manufacturing with sensors

Jeremy Swinfen Green explains how emerging sensor technologies are driving growth and profitability

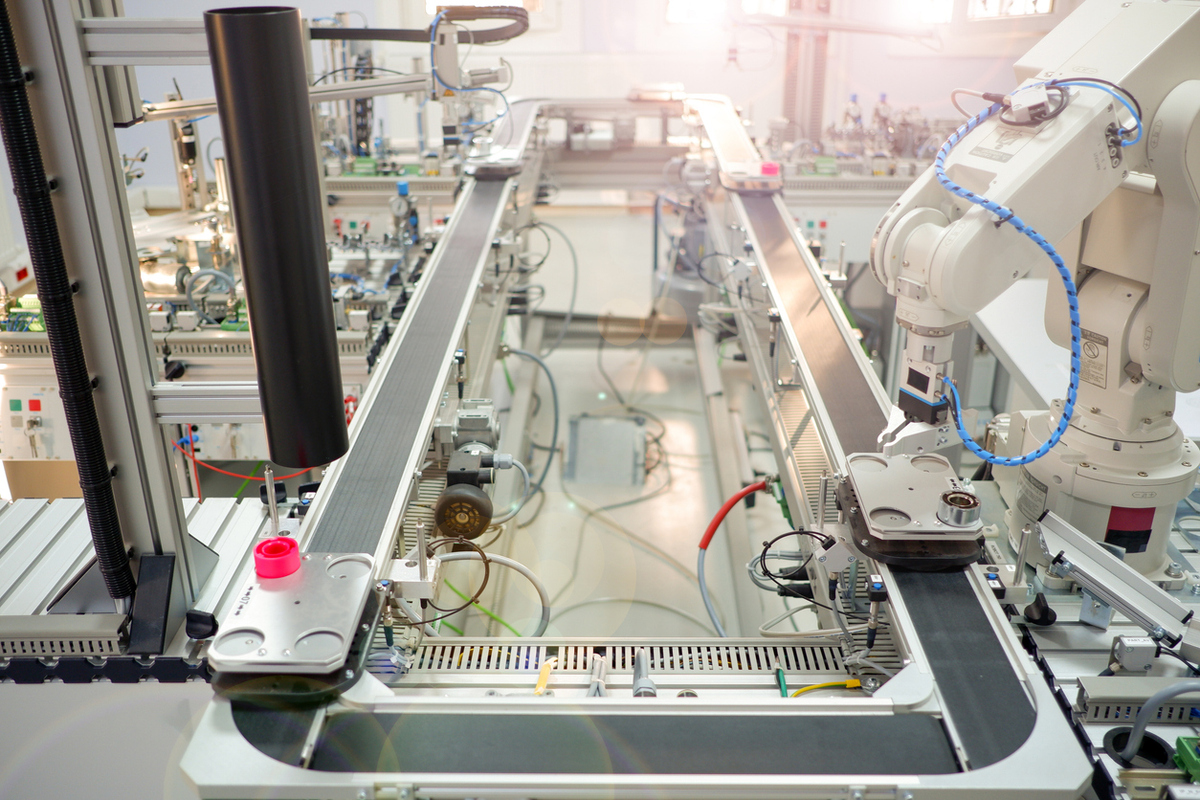

The manufacturing industry is changing rapidly. Global competition, shifting customer expectations, skill shortages and the pressure to operate more sustainably are forcing businesses to rethink how they make and deliver their products.

Senior decision-makers must balance productivity, flexibility and safety if they are to drive growth in a volatile and highly regulated marketplace. A key part of the solution lies in emerging sensor technologies, which have the potential to provide real-time data so that manufacturing processes can be optimised.

But sensors can also be used to monitor product quality and volumes, ensure worker safety by detecting potential hazards and reduce costs through predictive maintenance and minimised waste. Increasingly in manufacturing, robotic ears listen for early signs of mechanical failure; electronic noses sniff out chemical leaks before they become hazardous; and computer vision systems inspect thousands of products a minute.

Sensors are bringing intelligence to every corner of the factory floor, turning data into a strategic asset and making manufacturing smarter and ever more profitable.

Productivity as a lever for growth

For decades, productivity improvements in manufacturing were achieved through a combination of incremental process improvements, lean management techniques and automation. These remain important, but sensor technology is taking efficiency gains to a new level.

Take acoustic sensors as an example. Machines make their own unique sounds during normal operation. When parts such as bearings, pumps or motors begin to wear, subtle changes in those sounds occur. By listening for those changes, sensors can identify emerging faults long before they cause problems. Instead of halting production for unplanned repairs, maintenance teams can intervene at the right moment, extending equipment life and avoiding costly disruptions.

Optical sensors also offer a boost to productivity. Manufacturers used to measure product quality by taking random samples. However, this allowed some defective goods to slip through. With high-speed computer vision systems, every product is inspected and defects are identified in real time, reducing returns.

Motion sensors improve the flow of materials and people across the factory. By tracking automated guided vehicles, robotic arms and sometimes even human workers, manufacturers can analyse movement patterns, eliminate bottlenecks and refine workflows.

The use of sensors to fine-tune manufacturing operations allows productivity to rise without the need for significant additional investment in equipment or labour.

Flexibility in a changing marketplace

The modern consumer is more demanding than ever, expecting personalised products, rapid delivery and consistent quality. Manufacturers are being forced to respond by exchanging long production runs with little variation for shorter, customised batches. These are almost inevitably less profitable. However, flexibility is now a core capability, and sensor technologies enable businesses to become more agile while maintaining profit levels.

Optical sensors, particularly when combined with artificial intelligence, give manufacturers the ability to handle different product shapes, sizes and colours without lengthy reprogramming. Production lines can shift seamlessly from one model to another, making it possible to offer customised options without sacrificing efficiency.

Motion sensors are also reshaping how human workers and robots interact. Collaborative robots, or cobots, rely on motion detection to adjust their actions in real time as people move around them. This allows production environments to be reconfigured quickly, without needing to erect barriers or enforce rigid separation between humans and machines. The result is an agile workforce where humans and robots complement each other’s strengths.

For business leaders, flexibility means more than operational agility. It translates directly into competitive advantage, enabling companies to respond faster to shifts in demand, bring new products to market more quickly and scale production up or down without prohibitive cost.

Safety and the human factor

Manufacturers cannot only look outward at customers and shareholders. They also need to look inwards at their workforce. Part of this involves addressing safety. Safety failures carry enormous consequences, from demotivated employees to lost time, and from compensation claims to regulatory fines and reputational damage. And here, too, sensor technology is proving transformative.

Acoustic sensors can detect irregular vibrations or air leaks that may signal an imminent mechanical failure. By addressing the issue before it escalates, businesses prevent accidents that could injure workers or damage facilities.

Olfactory sensors play an even more direct role in safeguarding people. By detecting toxic gases, volatile chemicals or fires, especially in places where no humans are present, they provide an early-warning system that allows for swift evacuation or corrective action. In industries such as petrochemicals or pharmaceuticals, this capability can mean the difference between a contained incident and a catastrophic event.

Motion sensors enhance safety by creating dynamic protective zones around hazardous equipment. If a worker inadvertently steps too close to a robotic arm or enters a restricted space, the system can automatically halt operations. This prevents accidents and also builds confidence among employees who might otherwise be reluctant to work alongside advanced machinery.

Optical sensors contribute by monitoring compliance with safety protocols. They can verify whether workers are wearing the correct protective equipment or flag unsafe behaviours in real time. By embedding safety into workflows, optical systems reduce reliance on human supervision and create an environment where best practices are reinforced continuously.

For decision-makers, the safety benefits of sensors extend well beyond compliance. A safer workplace is a more productive one, with higher morale, lower staff turnover and reduced risk exposure.

Beyond efficiency: strategic business benefits

While productivity, flexibility and safety are the most visible advantages, sensor technology delivers additional strategic benefits that strengthen the business case for investment.

Costs can be significantly reduced. By monitoring when machines are running unnecessarily or when lighting, heating and air conditioning can be scaled back, sensors help businesses cut energy costs significantly. With more precise process control, manufacturers can minimise their use of raw materials.

Perhaps most importantly, sensors can improve the speed and accuracy of decision-making by providing a detailed and accurate view of performance. This allows better forecasting and more efficient maintenance scheduling. Instead of relying on historical data or gut instinct, executives can make decisions based on real-time operational intelligence.

The result is greater customer satisfaction. Higher product quality and faster delivery time build brand trust, repeat business and long-term loyalty.

From operations to strategy

The role of sensors in manufacturing has shifted dramatically. Once seen as technical tools for engineers, they are now also strategic assets for senior leaders. By embedding intelligence throughout the production environment, businesses can move from reactive to proactive management, from rigid to agile production, and from compliance-driven safety to a culture of resilience and innovation.

With the significant benefits they bring, the question is no longer whether sensor technologies belong in manufacturing but how soon they can be deployed at scale. Companies that embrace them are setting new standards for efficiency, agility and resilience. Those that hesitate risk being left behind in an increasingly demanding and competitive marketplace.

Jeremy Swinfen-Green

Related Articles

Related Articles

Most Viewed

Winston House, 3rd Floor, Units 306-309, 2-4 Dollis Park, London, N3 1HF

23-29 Hendon Lane, London, N3 1RT

020 8349 4363

© 2025, Lyonsdown Limited. Business Reporter® is a registered trademark of Lyonsdown Ltd. VAT registration number: 830519543