How digital manufacturing is powering a new era for European industry

Sponsored by Xometry EuropeEuropean manufacturers are rethinking how they produce – adopting digital tools and smarter sourcing strategies to stay resilient in an unpredictable world

From Leeds to Seville, European manufacturers are navigating one of the most transformative periods in decades. The pressures of cost volatility, supply chain uncertainty and the growing need for innovation are forcing businesses to rethink not just what they make, but how they make it.

According to the Manufacturing Outlook 2026, published by Xometry, 82 per cent of European manufacturers now view AI and automation as critical for future growth. What was once a competitive edge is now a prerequisite for survival.

Recent years have shown that traditional procurement models, while reliable, can benefit from greater speed and flexibility. Digitalisation is now filling that gap – transforming how products are designed, sourced and delivered across Europe’s industrial landscape.

Agility becomes the new scale

“Digital platforms are levelling the playing field,” says Ole Marx, Xometry’s Regional Sales Director. “They give companies of all sizes – from startups to large industrial players – access to the same technologies, capacity and manufacturing expertise.”

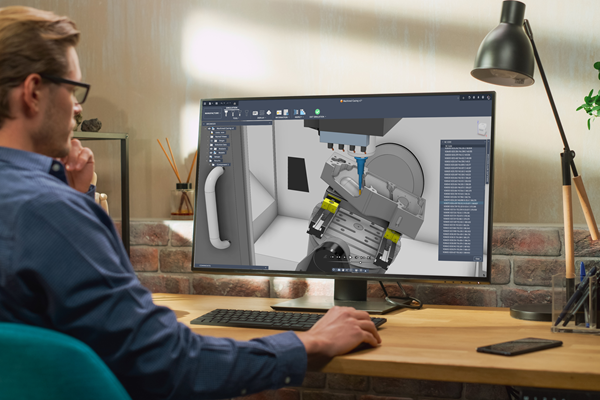

Through platforms such as Xometry, engineers can upload a CAD model and receive an instant, AI-generated quote, connecting them with a global network of more than 10,000 qualified suppliers.

For manufacturers, this access can be transformative. It allows them to produce only when needed, in the desired quantity, without investing in expensive machinery or building large procurement teams. That flexibility helps them stay competitive – and frees up time and resources to focus on what matters most: design and innovation.

Smarter sourcing, real results

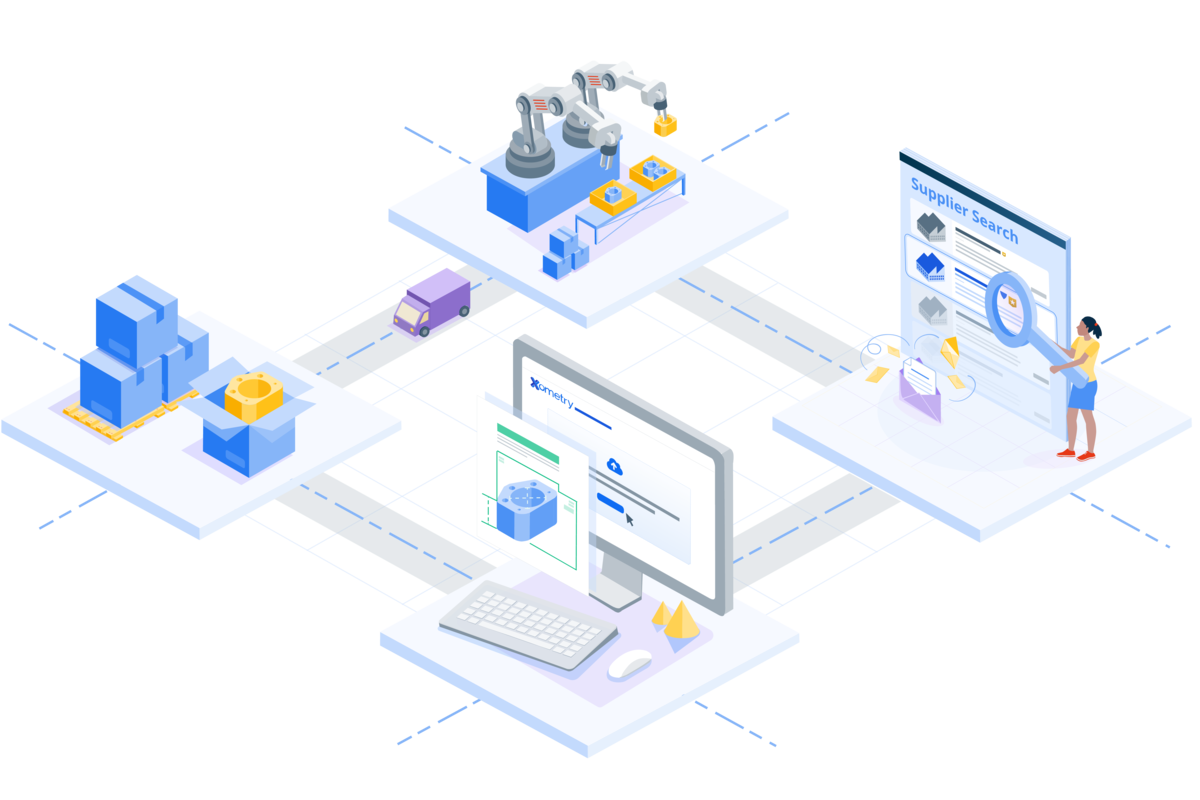

Modern manufacturing isn’t just about making parts faster, it’s about making smarter decisions. Tools such as Target Price Orders let procurement teams set their desired price point and automatically match their project with the best supplier available within budget.

“It’s a new way of managing production,” explains Marx. “You decide your priorities – cost, lead time or technology – and the platform gives you visibility and control. That transparency reduces uncertainty and allows companies to move with confidence.”

Marx adds that supply chain agility has become a defining advantage. “Today, companies need to know that if one supplier encounters disruptions, another can seamlessly take over. That flexibility is what keeps production moving – and it’s where digital manufacturing shows its real strength.”

By leveraging a broad and dynamic supplier network, manufacturers can ensure continuity even under pressure. The ability to adapt fast and maintain delivery in changing conditions is no longer just a safeguard – it’s a strategic capability for modern industry.

Balancing technology and human insight

Behind the automation lies a human element that remains essential. “Artificial intelligence can accelerate analysis and logistics,” Marx notes, “but human expertise is what ensures quality and helps customers find the right technical solutions.”

At Xometry, engineers and production managers work closely with clients to validate designs, suggest materials and guide complex projects. It’s a partnership between digital precision and human judgment. One that helps businesses of all sizes operate more efficiently and creatively.

The future is connected

As European manufacturing continues to evolve, one trend is undeniable: the future is connected, collaborative and data-driven. Companies no longer need to rely on a single supplier or region. Instead, they can access a global ecosystem that adapts to their needs.

Digital manufacturing platforms are at the heart of this transformation, allowing businesses to source smarter, innovate faster and build supply chains that are both flexible and resilient.

In this new industrial era, success won’t be defined by who produces the most, but by who adapts the fastest.

Discover the key trends shaping European manufacturing in Xometry’s Manufacturing Outlook 2026

To learn how Xometry is helping European manufacturers build smarter, more agile supply chains and bring ideas to life faster, visit www.xometry.eu

Business Reporter Team

You may also like

Most Viewed

Winston House, 3rd Floor, Units 306-309, 2-4 Dollis Park, London, N3 1HF

23-29 Hendon Lane, London, N3 1RT

020 8349 4363

© 2025, Lyonsdown Limited. Business Reporter® is a registered trademark of Lyonsdown Ltd. VAT registration number: 830519543