Drive ROI and gain the competitive advantage: get your PLM and ERP in the right order

Sponsored by Centirc SoftwareChristophe Therrey, Centric Software Senior VP of Sales EMEAR and Global New Markets, sheds some light on the ongoing PLM versus ERP debate

In today’s financial climate, businesses are often faced with tough decisions when it comes to tech investments. The consumer goods industry is plagued with challenges such as rise of material costs, geopolitical events, new regulations and shifting consumer trends, affecting every team in a business and asking them to pivot quickly.

This agility can only be achieved if systems are connected enabling teams to make decisions quickly based on the same information. By being more agile, businesses can ultimately be more competitive.

Given the need for agility and seamless integration, PLM and ERP are two enterprise systems that are no longer optional. Each technology brings unique value, but one has a more immediate impact on return on investment (ROI). However, there is still some confusion on which system does what.

Two must have enterprise systems – PLM and ERP – but what’s the difference?

ERP focuses on manufacturing. It originated as a manufacturing resource planning system, which then morphed into enterprise resource planning. ERPs focus on improving operational, transactional processes such as finance, operations, inventory management, manufacturing, reporting and HR.

PLM systems enable companies to create better products and manage all data related to product creation. PLM encompasses all the iterative, collaborative and creative processes that make up the vital elements of a product’s lifecycle. A good way of looking at it would be to consider that the chronology associated with PLM and ERP work differently.

PLM manages the data as it relates to the product development cycle over time. While ERP can improve operational excellence, PLM can do that and more. For example, PLM can optimise sourcing. If there is an issue with one supplier, users can replace the supplier with another, already-identified, qualified supplier in PLM. But PLM also delivers ROI. Numbers Centric Software has seen include:

- A 25 per cent reduction in sample lead times

- A 30 per cent improvement in design productivity

- A 75 per cent increase in category manager capacity

- A 30 per cent increase in bill of materials (BOM) accuracy

In terms of benefits, ERPs take a finished product to store shelves, provides commercial information such as cost, price and margin, but they do not make companies better that the competition.

PLMs do. No one is going to beat the competition because they’ve processed an invoice really well! With PLM for example, businesses will improve margins by managing supplier negotiation and pricing in the tool, which affects COGs and ultimately the bottom line.

But the question is, which to implement first?

Whether to implement ERP or PLM first is a common dilemma. Both are necessary for brands, retailers and manufacturers.

There are three potential strategies for implementing these systems: initiating with PLM followed by ERP; starting with ERP then moving to PLM; or opting to implement both PLM and ERP concurrently.

All three are acceptable, but there is timing associated with each. The deployment of an ERP typically takes much longer than PLM. A proper PLM go-live takes six months at most from kick-off, which is good for change management. People adopt PLM more readily, and these quick wins are important when it comes to digital transformation to keep the momentum going.

Another compelling reason to get PLM in first is that ERPs need accurate and up-to-date master data to take full advantage of the system. Without that clean data from PLM, the input to ERP would have to be populated somewhat manually. This is cumbersome, time consuming, prone to error and resource-intensive. Further, it will take even longer to get the ERP fully operational.

What to look for in PLM providers

There are a number of considerations when looking for a PLM provider. One of the first is talking to references in the same industry. This is a step that companies tend to skip, but that’s a mistake. Selection teams should absolutely check to hear from those who already are using the system. What are they saying? Is the system user friendly? Has it truly streamlined workflows? How was the implementation?

Another consideration is whether the PLM is a true out-of-the-box solution. That means it has all the functionality built in but can be configured to each company and even individual users’ needs without any hard coding.

Next, look at the depth of coverage the solution is providing. Besides the usual PLM functions, does it perform other roles such as enabling sustainability and handling regulatory compliance?

Lastly, look at the knowledge of the vendor’s team. What is their experience in consumer goods? A valuable PLM provider’s team will have the expertise that can guide a company through implementation based on industry best practices. While it may appear demanding, companies must ensure their selected vendor can meet the challenge.

The future of enterprise systems

Recently, there has been much talk about software as a service (SaaS) and the cloud. But really, that is a debate of the past. Yes, it makes integration a little bit easier, but the large expected jump in productivity just isn’t there.

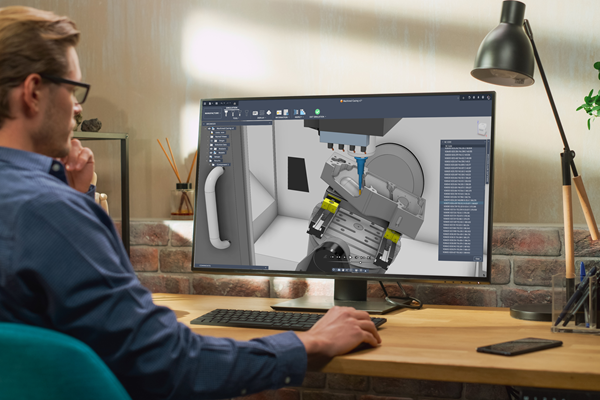

The future lies in the scalability of systems but also how open systems are to integrate into one or another. Being ERP-agnostic, like being 3D-agnostic, is at the heart of our product roadmap. Consumer goods brands and retailers all come with their specific IT landscape. The idea is not to disrupt everything but rather work with all systems in place.

When it comes to building a product ideation to consumer platform, Centric offers a one-stop shop, from planning and PLM to pricing and inventory. Why have multiple vendors when you can have just one that takes care of all integrations like ERP.

Finally, you can’t discuss the future without mentioning artificial intelligence. AI-powered platforms automate tasks and make decisions based on data that keeps getting more accurate with larger amounts of input. Machine learning technology is already here and in Centric Software systems, but in terms of what it can do for businesses, the potential is just beginning to be realised. A modern PLM vendor has AI-fluency, has already begun to integrate AI into its solutions, and is ready to connect other specialised AI-systems to PLM for seamless expansion of depth of capabilities for each particular use-case.

Want to learn more about consumer-goods-focused, flexible Centric PLM?

Business Reporter Team

You may also like

Most Viewed

Winston House, 3rd Floor, Units 306-309, 2-4 Dollis Park, London, N3 1HF

23-29 Hendon Lane, London, N3 1RT

020 8349 4363

© 2025, Lyonsdown Limited. Business Reporter® is a registered trademark of Lyonsdown Ltd. VAT registration number: 830519543