AI-powered vehicle safety moves into heavy industries

Sponsored by Via Tech

Over the past decade, safety technology in passenger vehicles has been transformed. Rear-view mirrors and basic proximity sensors have been supplemented – and in some cases replaced – by radar- and camera-based systems capable of a wide range of functions, from detecting blind spots and alerting drivers to nearby pedestrians, to warning of vehicles ahead on the road.

By contrast, the multi-tonne vehicles used across construction sites, waste collection operations and long-distance freight have lagged behind. While significant investment has gone into developing advanced driver-assistance systems (ADAS) to improve comfort and safety for everyday motorists, far less attention has been paid to the specialist operators of trucks and heavy machinery – despite the elevated risks associated with their work. In many cases, these vehicles are still operating without even basic camera systems.

The result has been a critical technology gap. However, a new generation of AI-driven safety solutions for heavy industries is beginning to close it, improving not only safety outcomes for workers in sectors such as mining and logistics but also operational efficiency for the businesses that rely on them.

Intelligent safety systems

At first glance, the imbalance in safety innovation is understandable. The passenger vehicle market is far larger and more standardised, making it easier to design and deploy technologies at scale. Cars and family vans are broadly similar in size and configuration, allowing cameras and sensors to be used across multiple models.

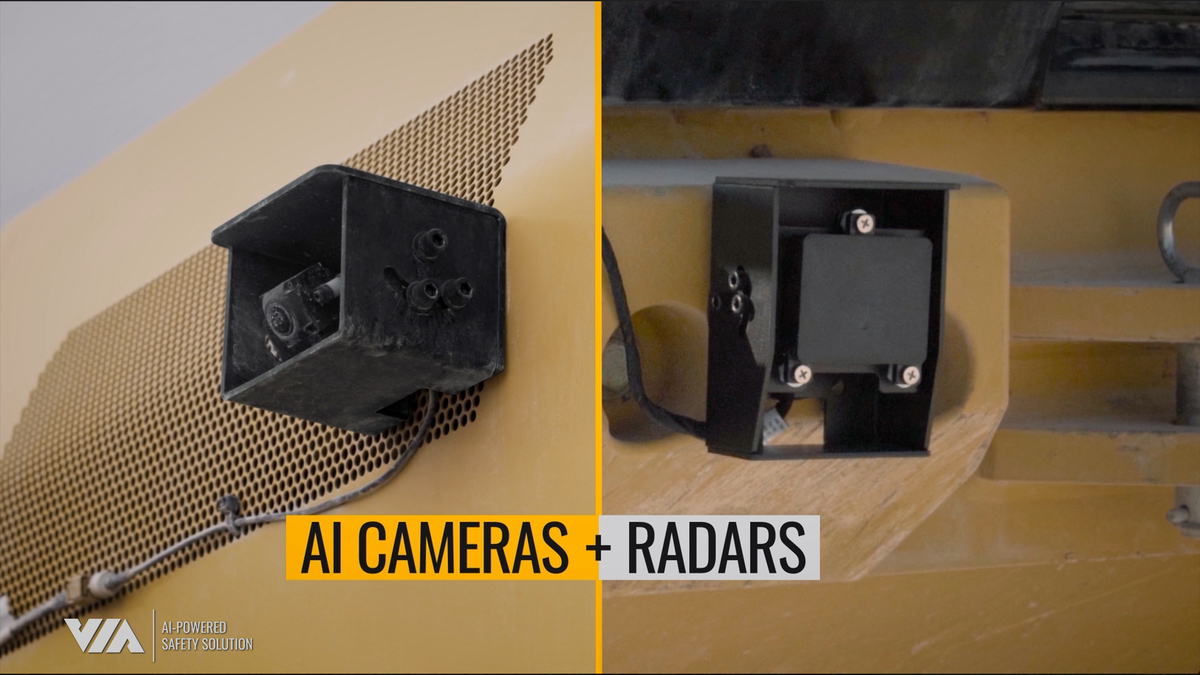

Heavy vehicles, by comparison, differ widely in shape, size and function. A radar system designed for an articulated lorry would be ineffective on a haul truck, just as a camera suited to a delivery van would fail on an aircraft tug. This variability has made safety technologies more difficult to adapt and scale.

Yet, just as inadequate safety features in cars pose a risk to pedestrians, the absence of equivalent ADAS solutions in heavy industry places workers in danger. On construction sites worldwide, multi-tonne vehicles frequently reverse with limited visibility while workers nearby may have their backs turned. These scenarios occur daily – and too often result in injury.

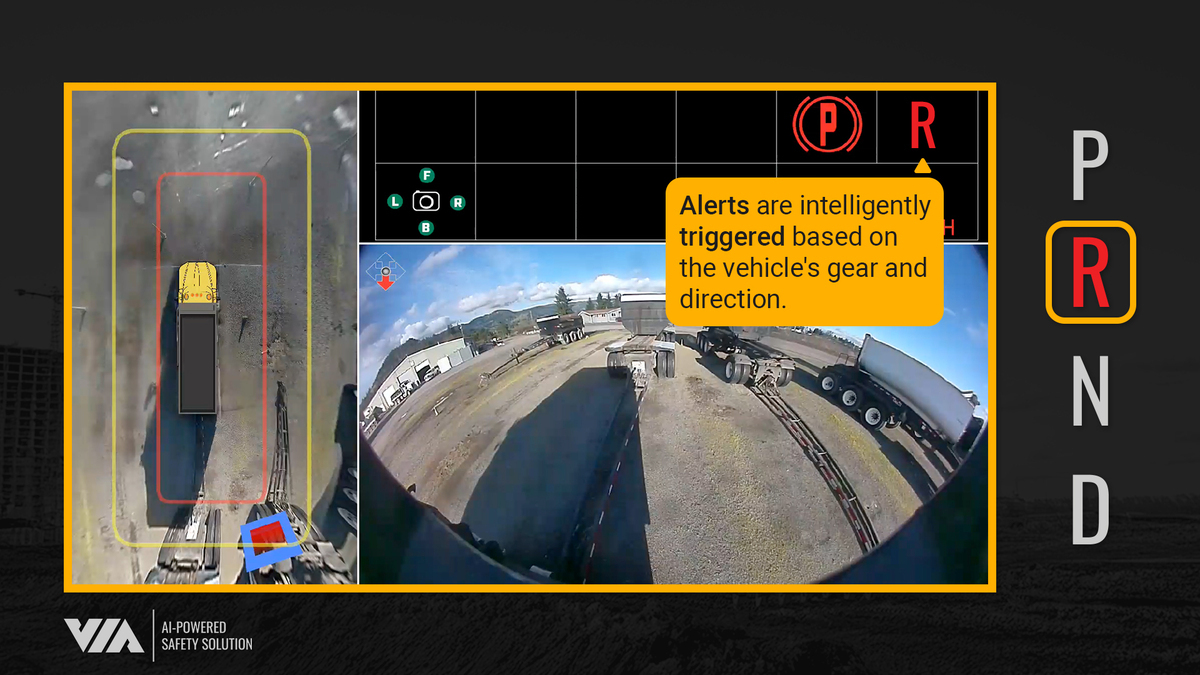

According to VIA Technologies, which develops AI-powered solutions designed to improve operational safety and efficiency, the answer lies in building an intelligent, context-aware safety ecosystem that protects everyone on site while delivering actionable insights. Rather than refining traditional approaches dominated by reactive alerts, the company has taken a fundamentally different approach to workplace safety.

“Reactive measures are obsolete because they rely on indiscriminate alarms that beep regardless of context,” says Epan Wu, Corporate Vice President at VIA Technologies.

“Equally important is matching the technology to the vehicle’s scale. While a utility truck may rely on a precision AI backup camera to monitor its danger zone, large dump trucks and waste collection vehicles have blind spots on all sides, requiring a full 360-degree view to properly secure their surroundings.”

Context-aware technology

VIA Technologies has developed a comprehensive safety approach for heavy vehicles that combines 360-degree surround-view systems, external pedestrian alerts and intelligent software. The aim is to create a complete safety perimeter around the vehicle – not just warnings for the driver inside the cab.

This is particularly important in environments such as mining and waste management sites, where workers are regularly exposed to constant alarm sounds. Over time, this can lead to “alert blindness”, as individuals become desensitised to the noise.

The reason is simple: a generic alarm provides little meaningful information. It may originate from a vehicle that poses no threat, or be triggered by an object rather than a person. With no way to assess relevance, workers naturally begin to ignore the sounds altogether.

By contrast, VIA Technologies’ system is context-aware. It processes significantly more data than traditional safety solutions, enabling it to understand the specific situation the vehicle and operator are in. Alerts are triggered only when genuinely necessary. This reduces unnecessary noise while improving accuracy – resulting in safer sites, improved staff retention and more efficient operations.

“This approach is about reducing cognitive strain,” Wu explains. “Drivers in these environments are already managing multiple inputs, from radio communications to complex routing instructions. A clear, comprehensive view of hazards cuts through that noise, supports better decision-making and allows drivers to focus on the tasks that truly matter.”

A proactive safety culture

By extending the safety zone beyond the cab, this technology also protects vulnerable ground personnel. Exterior Warning Lights and Alarms provide clear, targeted warnings to pedestrians who may be distracted or positioned in a vehicle’s blind spot, with alerts ceasing only once the individual has moved to safety.

In doing so, advanced vehicle safety innovation is finally expanding beyond its traditional focus on passenger cars and into heavy industry. Rather than being treated as a compliance requirement, it is increasingly recognised as a strategic investment – one that enhances efficiency, improves operator retention and helps foster a proactive safety culture.

Discover how VIA Technologies can transform the safety ecosystem of your fleet

Business Reporter Team

You may also like

Related Articles

Most Viewed

Winston House, 3rd Floor, Units 306-309, 2-4 Dollis Park, London, N3 1HF

23-29 Hendon Lane, London, N3 1RT

020 8349 4363

© 2025, Lyonsdown Limited. Business Reporter® is a registered trademark of Lyonsdown Ltd. VAT registration number: 830519543